3D-printed microwave cavities

Key members:

- Gaetano Mileti (gaetano.mileti@unine.ch)

- Christoph Affolderbach (christoph.affolderbach@unine.ch)

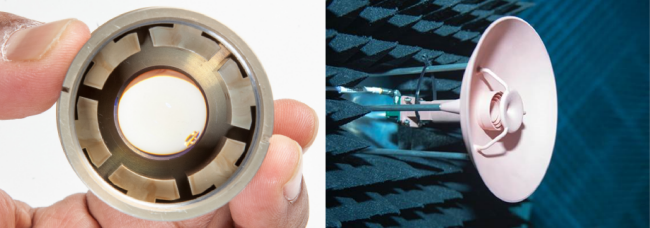

Microwave cavities are critical key components in many types of atomic clocks, where they produce a reference signal that allows obtaining an ultrastable frequency, which in turn enables the desired long-term stability and precision of the atomic clock. The fabrication of such microwave cavities requires high precision in the machining of metals, which is challenging and cost-intensive with today’s standard techniques. In this project we will study and demonstrate the manufacture of microwave cavities using additive manufacturing techniques, also known as 3D printing. The use of 3D printing for manufacturing other types of microwave components has been developed for example by the company SWISSto12 SA, but has not yet been demonstrated for resonant structures such as microwave cavities. Within this project, a microwave cavity will be fabricated using 3D printing, and will be tested and evaluated in a laboratory demonstrator atomic clock setup, for the example of a vapor-cell Rubidium atomic clock.

The 3D-printing approach has great potential to strongly simplify the manufacturing of microwave cavities, leading to reduced production cost. It also provides increased flexibility for the production of small series of microwave cavities with complex geometries, and thanks to the materials used for 3D printing, these components can be more lightweight than conventional ones, which is of advantage for atomic clocks intended for mobile or satellite-borne applications.

Read the project final summary.

The project results were presented at the event Space Technologies Studies 2016: results organized by the Swiss Space Center on February 13, 2018.

The peer-reviewed article "Study of additive manufactured microwave cavities for pulsed optically pumped atomic clock applications" resulting from this project was selected as "Editors' pick" by Applied Physics Letters on March 16, 2018.

Left-hand side: Conventional microwave cavity design. Right-hand side: microwave antenna manufactured by SWISSto12 3D printing technology (Image courtesy European Space Agency). Download high-resolution photo.

This project is conducted in collaboration with the company SWISSto12 SA and the Laboratory of Electromagnetism and Acoustics at EPFL.

Funding : Space positioning measures of the Swiss Space Office of the State Secretariat for Education, Research and Innovation of the Swiss Confederation (SERI/SSO) .